A semi-dry mortar screed, also known as traditional screed, has a consistency called “damp soil”. Mixing is carried out on site in concrete mixers or by means of pneumatic mortar conveyors, also called “floor screed machines” or “screed pumps”, which allow the mortar to be mixed, pumped from the mixing vessel via a screed hose and discharged in the correct location.

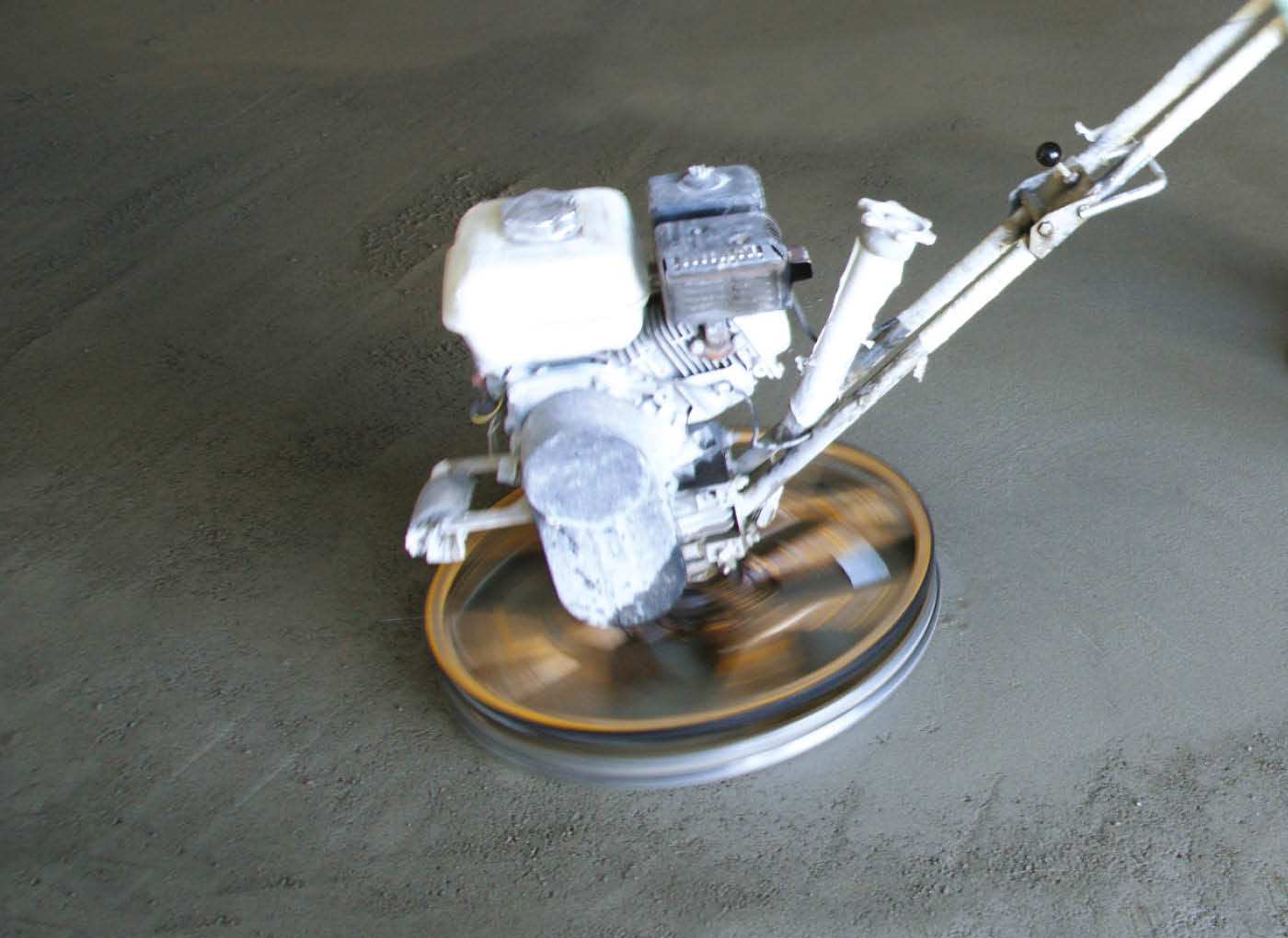

The semi-dry mortar is spread to the required depth, compacted, levelled with a straight edge and then finished using a float and a steel trowel according to the desired surface condition.

The application technique is traditional, relatively simple and is usually carried out by floor screed specialists or tiler masons.

This type of screed, due to the consistency of the semi-dry mortar, can also be applied on sloping surfaces or to create slopes on flat surfaces. It is suitable for small surfaces as well as for large areas.

Laterlite. specialist in screeds for more than 30 years, offers a wide range of semi-dry bagged screeding mixes, ready to mix with the only addition of water, that are specifically designed for the different requirements and needs of each construction site:

Lightweight semi-dry screeds, based on Expanded Clay aggregate:

- Latermix Fast: fibre-reinforced, fast drying screed, for low depth application and for internal and external use.

- Latermix Forte: shrinkage-compensated, controlled drying screed for internal use only.

- Latermix Facile: multi-purpose, for internal and external use.

- Latermix Cem Mini: ultra-lightweight and versatile, for internal and external use (semi fluid consistency)

Semi dry screeds base on normal weight aggregates Massettomix,:

- Paris 2.0: high conductivity underfloor heating screed, reinforced with metallic fibres for internal use only.

- Pronto: fast drying high strength screed, for low depth application, and for internal and external use.

A flowing screed mortar, also called free-flowing, self-levelling or liquid screed, has a very fluid consistency (self-levelling) and requires a completely different application method than semi-dry traditional screeds.

Laterlite self-levelling screeds, for interior use, are mixed and pumped on site from bagged premixed products. Mixing is carried out by professional applicators with continuous screed mixer pumps delivering the mix to the application location via a hose. For smaller surfaces and thicknesses, it is also possible to mix the products in suitably sized containers using a hand-held electric paddle mixer.

The fluid consistency of this type of product allows it to flow by gravity and spread into all spaces. Before laying a flowing screed mortar, the substrate must be carefully prepared to avoid leaks and infiltrations or water absorption.

The flowing screed is poured in a single, uninterrupted operation, starting at the lowest point of the workpiece. To achieve a smooth durable and accurate finish, a self-levelling screed dapple bar (also called tamping bar) is used to release air bubbles and lightly break the surface tension. In case of low depth application, the entire surface is rolled over with a spiked roller.

Flowing self-levelling screeds provide a very smooth finished surface, ideal for laying any floor finish.

Laterlite’s bagged flowing screeds are :

- Paris SLIM : low thickness self-levelling screed, ideal for underfloor heating.

- Ultra SLIM: levelling compound

- Autolivellante : flowing screed